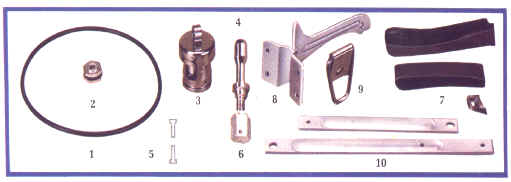

Parts of the Pelican Pressure Cooker

All the parts of the Pelican Pressure Cooker are rigorously tested to meet the Bureau of Indian Standard. Given Below are the different parts of the Pelican Pressure Cooker and the ISI Standards the confirm to.

Rubber Gasket: is vital for a quality pressure cooker. The gasket shall be confirming to hardness, tensile strength & elongation as per IS7466.

Safety Valve: is an important part of the pressure cooker. The alloy composition of the safety valve shall be such that it melts before the gauge pressure is reached greater than half of the bursting pressure i.e. 3 Kgs per cm sq. The weight of the safety valve is 15 to 16 grams as per IS2347.

Pressure Regulating Device: or Vent weight is made of brass and stainless steel, conforming to ISI standards. The thickness of the Chrome plate is as per IS1068

Vent Tube: the material used is nickel chrome plated brass with SS bush inserted conforming to ISI standards.

Vent Seal Pin: for pressure regulating device made of S.S. conforming to IS 6527.

Vent Tube Nut: is made of Aluminium.

Bakelite Main Handle, Bakelite Lid Handle, Auxiliary Handle: are made from impact resistant and non inflammable plastic as per IS13395.

Aluminium Main Handle: is made from aluminium alloy checked lot-wise as well as an independent laboratory.

Locking Loop: is made out of pure stainless steel confirming to SAIL standards.

Lid Handle Bar: are purchased from leading manufactures confirming with ISI.

Cover Head: is made of aluminium extrusion of leading extrusion manufactures.

Stud and Screw: is made of Brass rod.

Aluminium Body: made of wrought iron conforming with IS20 or IS21.

Aluminium Lid: made of 2mm/ 3.25mm thickness, 35 Alloy conforming with IS20 or IS21.